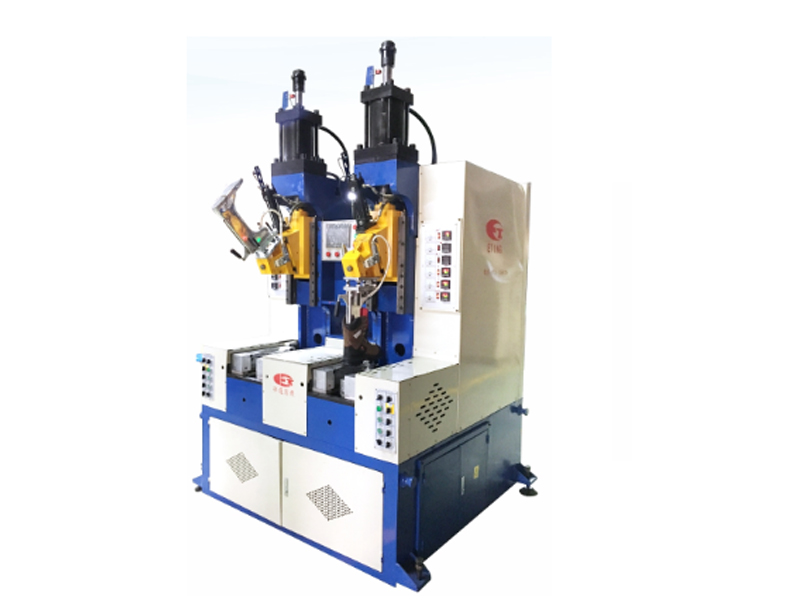

Rubber Dip Shoes Boots Making Machine

Technical Specifications are Indicative. Machines may Undergo Variations and/or modifications without any Previous Notice.

| ITEM | UNIT | SPECIFICATION |

| Number of stations | Station | 2 |

| Bottom core pressure | Mpa | 10 |

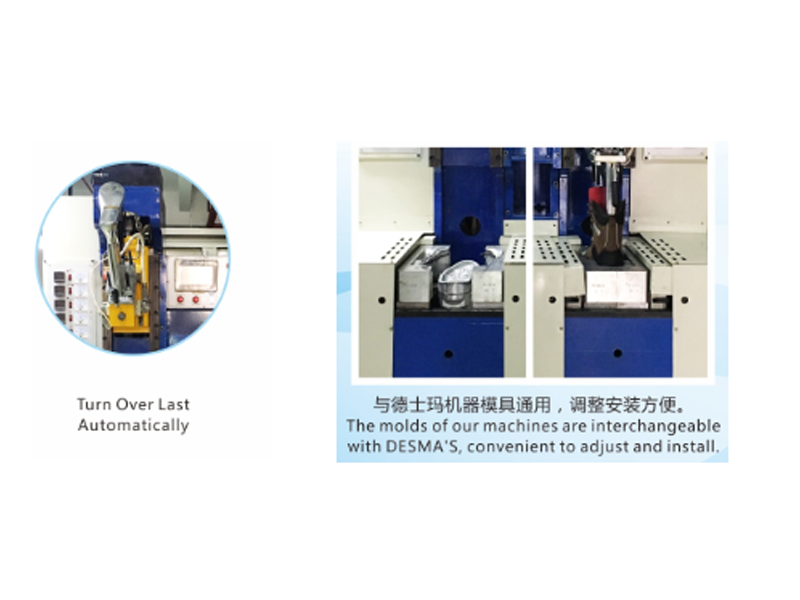

| Turn over last angle | ' | 180' |

| Stop turning last angle | ' | 0-180' |

| Mould frame dimensions (LxWxH) | mm | 430x200x75 |

| Clamp mold journey | mm | 65x2 |

| Last go up journey | mm | 150 |

| Bottom core up-down journey(adjustable) | mm | 40 |

| Oil tank volume | L | 235 |

| Pump motor power | KW | 5.5KW |

| Heating Power - Thereinto shoe last | KW | 300W x 4 1.2 |

| Heating Power - Bottom core | KW | 100KW x 2 2.0 |

| Heating Power - Side mold | KW | 900W x 4 3.6 |

| Outline dimensions (LxWxH) | mm | 1770x1550x2730 |

Product Display